Rooms managed at larger cleanliness class should have positive force differential when compared to the adjacent rooms.

Some classes never need tests some particle dimensions, because the concentration is too lower or far too higher to get useful to test for, but these types of blanks really should not be read as zero.

Grade D cleanrooms are dedicated to a lot less essential actions within the production of sterile prescription drugs. They serve several applications, such as:

Genuine-time Checking: As well as periodic sampling, utilizing authentic-time microbial monitoring devices delivers constant insights in to the cleanliness position in the cleanroom.

Discover Much more › What is really a Grade B cleanroom? › Quality A will be the cleanest and is particularly used for sterile functions. Quality B: This quality presents a history environment to allow aseptic preparing and filling for many grade A zone items.

Usually, gowning necessities turn into more stringent as you progress from the decrease class (like Class D) to a greater class (like Class C). Below’s a general notion of what is likely to be demanded:

Versatility: A modular cleanrooms is usually readily assembled, disassembled, and relocated, normally in just a couple of days or fewer

Time Preserving: Modular cleanroom devices can be put in onsite in a portion of the time as permanent construction.

Creating a GMP-compliant cleanroom involves mindful consideration of assorted components. Here are a few crucial style considerations to make sure GMP compliance:

The a few types of partitions for class 100 cleanrooms are difficult, soft, and rigid with challenging partitions getting manufactured from stable insulated materials when tender walls are created of various varieties of sturdy resilient polymers. The true secret distinction between the walls is the categories of elements from which They're designed.

The best threat to cleanroom contamination emanates from the consumers them selves.[18] While in the healthcare and pharmaceutical sectors, Charge of microorganisms is essential, especially microorganisms likely to be deposited to the air stream from pores and skin shedding.

[thirteen] UV get more info light-weight has Formerly been made use of to scrub floor contaminants in sterile environments for instance medical center functioning rooms. Their use in other cleanrooms might raise as equipment gets additional cost-effective. Probable benefits of UV-centered decontamination features a minimized reliance on chemical disinfectants and also the extension of HVAC filter daily life.

g., introducing managed amounts of billed ions into your air using a corona discharge. Static discharge is of individual worry while in read more the electronics business, exactly where it can right away ruin parts and circuitry.

Below at Lighthouse Worldwide Options, we’re all about just that: remedies. Alternatives for your personal particle counting needs, options for aiding you obtain your cleanroom classification, and remedies for that ups and downs that include Doing the job within a cleanroom.

Edward Furlong Then & Now!

Edward Furlong Then & Now! Taran Noah Smith Then & Now!

Taran Noah Smith Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now! Matilda Ledger Then & Now!

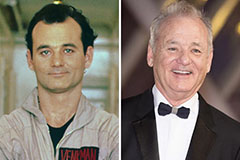

Matilda Ledger Then & Now! Bill Murray Then & Now!

Bill Murray Then & Now!